charpy impact test values for steel|charpy test sample dimensions : mfg Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with body-centered-cubic (bcc) crystalline materials. . Resultado da Enjoy improved textures and sharper resolutions, bringing your beloved Xbox 360 games to life. Install Xenia, unlock the doors to nostalgia, and let the gaming adventures begin on .

{plog:ftitle_list}

Ao criar uma conta no 166bet, você recebe automaticamente R$6,00 como um incentivo de boas-vindas, dando início à sua jornada de jogos com um impulso extra. Bônus do App .

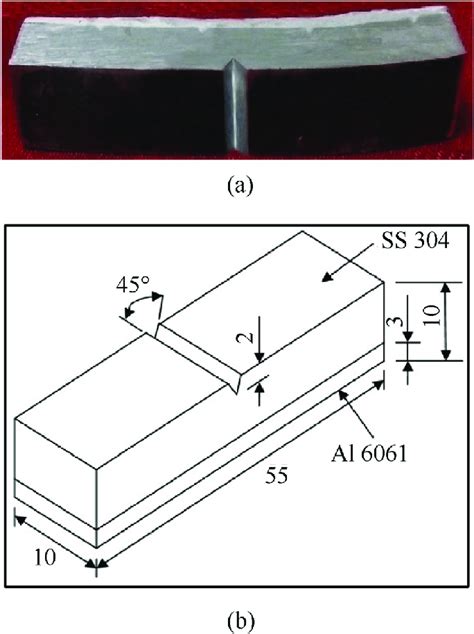

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally .

paint thickness testing methods

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.In this investigation, we performed instrumented Charpy tests in order to characterize the impact properties of three steels, used by NIST for the production of Charpy reference specimens .

Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with body-centered-cubic (bcc) crystalline materials. .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This method assesses the energy absorbed by a .

Charpy tests. Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .

Charpy impact testing, or V-notch testing, is an evaluation of a material’s strength and performance under impact conditions. It involves a pendulum with a pointed hammer on the end swinging and hitting a machined .

Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step .The Charpy impact energy values of both TIG welded RDE40 and AA7018 are summarized in the following Table 1 . Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested . a search of Charpy CVN values using A36 steel and E6013 electrodes w as . Charpy impact test and three-point bending test on 32 mm and 50 mm thick Q690 high-strength steel were carried out .

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. Quantitative data is data based on numerical values. In the Charpy impact test, this quantitative data is normally the energy absorbed during the fracture of the sample. The DBTT (Ductile-to-Brittle Transition Temperature) can also be estimated by testing the multiple samples at multiple temperatures to see where there is a drastic increase in .

impact testing of mild steel, the Charpy Impact Test can provide information on how much energy a specimen such as mild steel can absorb under an impact scenario. In this context, the following sections will present information on: 1) impact testing; 2) effect of .Table 1: temperature and impact energy values for steel. steel Temp °C -70 -44 0 25 100 Impact energy 10 (ft-lbs) 5 5 35 57 78 65 7 32 48 69 83 18 26 55 67 94 14 39 54 68 80 10 27 67 75 95 . The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture.Explore the Charpy impact test method for metallic materials as specified by the European EN 10045 standard. Understand the test's purpose, procedure, and the significance of the energy absorbed in joules. Learn about the designations, test pieces, and testing machines used.The Charpy impact test is particularly essential for materials used in parts that are subjected to strong impact or high pressure, such as those used in the power generation units and piping of nuclear power plants. . The impact value is derived from the energy at the time the test piece fractured, and is used to evaluate the toughness and .

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. . Charpy testing machine, a rod of mild steel and a rod of carbonate steel. . The pointer is .

Impact testing is required for many critical applications in the construction, machinery and equipment, defense, and energy markets. Charpy testing provides data needed to ensure the quality and reliability of structural steel products. Over 1,000 machines per year are evaluated for conformance with

charpy test sample dimensions

Experiment 7: Charpy Impact Test Name: Om Prabhu Roll Number: 19D170018 . Using the above calculated values of impact strength for mild steel, we can plot a graph of impact . For mild steel, impact strength is maximum at room temperature. ii)At lower temperatures, the material is more brittle and the fracture surface has a shiny, crys- . Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015).For impact testing of mild steel, the Charpy Impact Test can provide information on how much energy a specimen such as mild steel can absorb under an impact scenario. In this context, the following sections will present information on: 1) impact testing; 2) effect of temperature; 3) 17-4PH test material; 4) impact toughness of 17-4PH in H900 .

ABSTRACT Over the last five years, there have been numerous reports of failures of carbon steel A105 flanges, A234 Gr. WPB fittings and some A106 and A53 seamless pipe. The failures primarily occurred in newly constructed material and the nature of the failures was brittle fracture with very low Charpy V-notch values such as 4 Joules (3 ft-lbs) at temperatures .Figure 2. Test Specimens Used For Material Impact Testing IMPACT TESTING AT ROOM AND ELEVATED TEMPERATURES Reference 1 discussed the procedure used to perform the impact tensile testing of base material at room, 300 oF, and 600 oF temperatures. The procedure for testing the welded material at these same temperatures was identical. Hence, theThe value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen .impact testing machine the charpy ‘V’- notch impact test was carried out for weld metal. Gas tungsten arc welded joints using duplex stainless steel filler metal has higher charpy impact toughness values compared with the gas tungsten arc welded joints using austenitic stainless steel filler metals. The toughness value of

The measured parameters were used to simulate the Charpy impact test of armour steel specimen and reliable results were obtained. . When the pendulum velocity is less than the test value and changes by 4.68%, the maximum force and the impact absorption energy change by 2.45% and 4.96%, respectively; when the pendulum velocity is greater than .

The legends showing the values of magnitude of displacement with varying impactor velocities of maraging steel 300 in the Charpy impact test. (A) 5, (B) 6, (C) 7 and (D) 9 m/s.Calculators to help you find your Charpy V-notch values, yield and tensile values, temperature conversion, CE formula, CEQ/PCM, J factor, and x-bar. . Tool and Die Steel Plate. BACK; Request A Quote; 4140 Plate; C1045 Plate; Services. BACK; Request A Quote; Plate Cutting; . CVN Impact Forces. Enter Values and Click Submit. Ft/Lbs JOULES .

A Charpy impact testing apparatus, a device with a pendulum with various locking points at specified heights and a fixture to hold the test specimen, is used to determine Charpy impact strength. . ASTM A370 / ASTM E208: This standard governs impact testing for steel materials. Xometry provides a wide range of manufacturing capabilities .The Charpy-V test for characterising notch toughness is described. The qualitative nature of the test, outline procedures and test analysis are described. . quite arbitrarily, the temperature at which the metal achieves an impact value of 27 Joules - see, for example the impact test requirements of EN 10028 Part 2 Steel for Pressure Purposes.

In addition, a search of Charpy CVN values using A36 steel and E6013 electrodes was performed with wet welding. Finally, K IC-CVN correlations were presented to measure the fracture toughness. As conclusions they drawn that CVN impact energy and K IC values decrease as the sea depth increases. It is attributed to various discontinuities in wet . values in an API 5L X52 ER W steel in the L-T, T-L, S-T, T-S, L-S, S-L, and 45° directions with respect to the RD. . The Charpy impact test was performed after extracting samples in directions .

transferred to the Charpy testing machine, fractured, and the impact energy is measured. After . Table 1: temperature and impact energy values for steel. steel Temp °C -70 -44 0 25 100 Impact energy (ft-lbs) 5 35 57 78 65 7 32 48 69 83 18 26 55 67 94 14 39 54 68 80 . They estimated the fracture toughness of steel joints using Charpy impact tests [8] [9][10]. Similarly, Zhou and colleagues used Charpy impact specimens to obtain fracture toughness and thus .

charpy impact test standard pdf

R$ 399 / h. Tenho local. Marabá - Cidade Nova. Olá amores,prazer meu nome é Florence,trabalho com. Cadastre-se como contratante e tenha o a funcionalidades .

charpy impact test values for steel|charpy test sample dimensions